free miter saw table plans pdf

Explore free miter saw table plans with PDF guides, perfect for DIY enthusiasts. Build a sturdy workstation with easy-to-follow instructions, featuring storage solutions and mobile designs for enhanced productivity.

Overview of Miter Saw Tables

Miter saw tables are essential workstations designed to enhance precision and efficiency for woodworking projects. They provide a stable base for miter saws, ensuring accurate cuts and better control. These tables often feature side supports, storage compartments, and extendable wings for added versatility. Many free PDF plans offer detailed instructions, allowing DIY enthusiasts to build custom tables tailored to their workshop needs. With step-by-step guides and 3D diagrams, these plans make it easy to create a durable and functional miter saw station.

Importance of Using Plans

Using free miter saw table plans ensures a well-structured and professional build. Detailed step-by-step instructions guide DIYers through every phase, minimizing errors and saving time. Plans often include 3D diagrams and cut lists, making material preparation efficient. They also help in customizing the table to fit specific workshop needs, ensuring optimal functionality. By following a plan, builders can achieve precise measurements and a sturdy design, leading to better results and safer operations. This approach is ideal for both beginners and experienced woodworkers seeking reliable guidance.

Understanding the Importance of a Miter Saw Table

A miter saw table enhances precision, organization, and safety in woodworking projects. It provides a stable base for accurate cuts, keeps tools organized, and incorporates safety features for better control and results.

Enhanced Precision and Accuracy

A miter saw table significantly improves precision by providing a stable base for your saw. This stability ensures consistent alignment, allowing for accurate cuts every time. Features like side supports and clamps help secure materials, reducing movement during cuts. Proper alignment techniques are crucial, and a well-designed table facilitates this by keeping the saw positioned correctly. A clean workspace further enhances accuracy by minimizing distractions and keeping tools organized. These elements combined make a miter saw table indispensable for achieving professional-grade results in woodworking projects.

Workspace Organization

A well-designed miter saw table enhances workspace organization by providing a dedicated area for cutting materials. Built-in storage compartments, shelves, and hooks keep tools and accessories within easy reach, reducing clutter. The table’s design often includes wings or extensions for additional support, allowing for efficient material handling. A clean and organized workspace improves workflow, making it easier to focus on precision and safety. Many free PDF plans incorporate these features, ensuring your workshop remains tidy and functional for various projects.

Safety Considerations

Safety Considerations

When building a miter saw table, prioritize safety features to protect yourself and ensure smooth operation. Proper blade guards and emergency stop mechanisms are essential to prevent accidents. Dust collection systems help maintain visibility and reduce inhalation risks. Many free PDF plans include safety-focused designs, such as secure mounting systems to minimize blade wobble. A sturdy, well-built table reduces vibration and enhances control, creating a safer working environment. Always follow safety guidelines and consider adding features like emergency stops for added protection during use.

Key Considerations When Choosing Miter Saw Table Plans

Consider space, portability, and customization when selecting miter saw table plans. Ensure the design fits your workshop, budget, and specific tool requirements for optimal functionality and efficiency.

Space and Portability Needs

Consider your workshop’s available space and the need for mobility. Mobile miter saw stands with collapsible wings save space while providing extended support when needed. Portable designs often include wheels or handles for easy relocation, making them ideal for limited areas. Opt for plans that balance compactness with functionality, ensuring your table fits neatly into your workspace. Adjustable features like foldable supports can maximize efficiency without sacrificing portability, perfect for small garages or shared workspaces. Choose plans that align with your specific spatial and mobility requirements for optimal workflow.

Material and Budget Constraints

Choose materials that fit your budget while ensuring durability. Stud lumber and Simpson Strong-Tie hardware are cost-effective and sturdy options. Consider the size and features you need, as elaborate designs may increase costs. Opt for plans that offer flexibility in material choices, allowing you to use affordable alternatives without compromising functionality. Budget-friendly designs often focus on essential features, providing a practical workstation without unnecessary expenses. Prioritize your needs to maximize value and stay within your budget while building a reliable miter saw table.

Customization Options

Free miter saw table plans often include options for customization to suit your workspace and needs. Add extended wings for extra support or incorporate storage compartments for tools and accessories. Some designs allow for collapsible features to save space, while others offer the ability to add hooks or trays for organization. Advanced plans may include stop blocks for repeat cuts or integrated lighting systems to enhance precision. These customizable elements ensure your miter saw table can be tailored to your specific preferences and workshop requirements, improving functionality and efficiency.

Materials and Tools Required

Build your miter saw table using durable lumber, Simpson Strong-Tie hardware, and essential tools like a table saw, drill, and wrench for secure assembly and stability.

Lumber and Hardware Requirements

Constructing a miter saw table requires sturdy lumber, such as 2x4s or 2x6s for the frame and 3/4-inch plywood for the tabletop. Simpson Strong-Tie hardware ensures durability and stability. You’ll need wood screws, brackets, and bolts for secure assembly. Additional materials include sandpaper and wood glue for finishing touches. Optional features like casters or drawers may require extra hardware; Ensure all materials are weather-treated if the table will be used outdoors. Proper measurements and precise cuts are essential for a professional-grade finish.

Essential Power Tools

A miter saw table build requires a miter saw for precise cuts and a table saw for cutting lumber to size. A drill press ensures accurate hole drilling, while an impact driver efficiently secures screws. A circular saw is handy for ripping boards, and a sander smooths surfaces for a professional finish. Optional tools include a router for edge detailing. These power tools streamline the assembly process and ensure a sturdy, precise final product. Proper tool usage is key to achieving a professional-grade miter saw table.

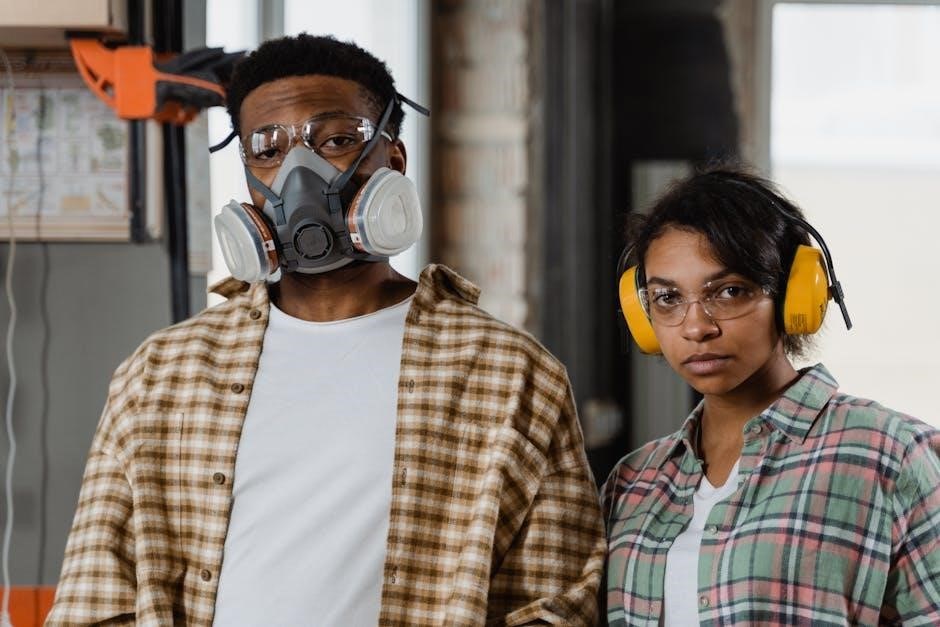

Hand Tools and Accessories

Essential hand tools for building a miter saw table include tape measures, clamps, wrenches, and screwdrivers. Utility knives are useful for scoring materials, while sandpaper ensures smooth surfaces. Safety accessories like gloves and goggles protect during assembly. Work lights illuminate the workspace for precise cuts and alignments. These tools complement power tools, ensuring a secure and accurate build. Having them on hand streamlines the assembly process, making it easier to achieve a professional-grade miter saw table tailored to your workshop needs.

Safety Features to Incorporate

Dust collection systems, proper blade guards, and emergency stop mechanisms are crucial for safe operation. Ensure all components are securely mounted to prevent accidents and maintain control during cuts.

Dust Collection Systems

A well-designed dust collection system is essential for a safe and efficient workspace. Install a dust port that aligns with your miter saw’s exhaust to minimize debris. Use a table saw to determine the exact location for dust collection boards, ensuring sufficient space beneath for a dust bag or connection. Properly securing these components prevents dust buildup and improves airflow. Many free plans include detailed instructions for integrating dust collection systems, ensuring a cleaner and safer cutting environment. Refer to downloadable PDF guides for precise measurements and setup tips.

Proper Blade Guards

Proper blade guards are critical for safe miter saw operation. Ensure the guard is correctly installed and aligned to prevent accidental contact with the blade. Many free PDF plans include instructions for integrating blade guards that provide optimal protection without obstructing the cutting process. These designs often feature adjustable guards to accommodate different materials and cutting angles. Always follow the manufacturer’s guidelines for blade guard installation to maintain safety and performance. Properly secured guards enhance precision and minimize risks in your workshop.

Emergency Stop Mechanisms

Emergency stop mechanisms are vital for ensuring safe operation of your miter saw table. Many free PDF plans incorporate easy-to-install solutions, such as paddle-style or foot-operated stops, to halt the saw instantly in case of an emergency. These mechanisms can be integrated seamlessly into the table design, providing quick access and reliable functionality. Proper installation ensures rapid response, minimizing potential hazards. Always prioritize these safety features when building your miter saw table to protect yourself and maintain control during cutting tasks.

Step-by-Step Building Guide

Begin your project with detailed step-by-step guides. Assemble the frame, install side supports, and securely mount your miter saw. Add wings and storage compartments for enhanced functionality and workspace efficiency.

Assembling the Frame

Start by constructing the frame using sturdy stud lumber and Simpson Strong-Tie hardware for durability. Ensure the base is level and securely attached to the floor or work surface. Measure and cut the frame components precisely, following the PDF plans; Use clamps to hold pieces in place while drilling pilot holes and tightening bolts. Proper alignment is crucial for stability. Install lower braces to reinforce the structure and provide additional support. Refer to the 3D diagrams for visual guidance. Sand all edges for a smooth finish before moving on to the next step.

Installing Side Supports

Attach side supports to the frame using 2×4 lumber, ensuring they are evenly spaced and aligned with the table’s edges. Secure them with bolts for maximum stability. Measure and mark the support positions carefully, ensuring the surface remains even. Use clamps to hold the supports in place while tightening the hardware. Check for levelness and adjust as needed. For added durability, consider adding adjustable feet to compensate for uneven workshop floors. Ensure all edges are sanded smooth for safety and proper material placement.

Mounting the Miter Saw

Position the miter saw in the table’s recessed area, ensuring proper alignment with the blade facing forward. Secure it using bolts provided with the saw or compatible hardware. Tighten firmly to prevent movement. Double-check the saw’s orientation and ensure the table surface is flush with the saw’s base. Use a square tool to verify alignment accuracy. Once mounted, test the saw’s operation to confirm smooth functionality. For added stability, consider adding a non-slip mat or adhesive foam under the saw’s base. Ensure all bolts are tightened evenly to maintain precision and safety during use.

Tips for Accuracy and Efficiency

Use clamps to hold materials firmly, ensuring precise cuts. Maintain a clean workspace to avoid debris interference. Regularly check and calibrate your miter saw for optimal performance.

Proper Alignment Techniques

Ensure your miter saw is calibrated accurately for precise cuts. Use jigs or guides to maintain consistent alignment. Always double-check measurements before cutting. For angled cuts, mark the material carefully and align the saw blade with the mark. Use clamps to secure the workpiece firmly, preventing movement during cuts. Regularly inspect the saw’s fence and blade for proper alignment. Consider using a laser guide or digital angle finder for enhanced accuracy. Test cuts on scrap wood can help verify alignment before working on your final project.

Using Clamps Effectively

Clamps are essential for securing your workpiece firmly on the miter saw table. Use C-clamps or bar clamps to hold materials in place, ensuring stability during cuts. Position clamps away from the saw blade to avoid interference. Apply even pressure to prevent warping or movement; Consider using clamp pads to protect delicate surfaces. For angled cuts, clamp the material at the desired angle to maintain accuracy. Additionally, clamps can help manage cables or accessories, keeping your workspace organized and safe.

Maintaining a Clean Workspace

Maintaining a clean workspace is crucial for efficiency and safety. Regularly sweep or vacuum dust and debris from the miter saw table and surrounding area. Use a dust collection system to minimize sawdust accumulation. Organize tools and materials in designated storage compartments to avoid clutter. Wipe down the table surface after each use to prevent dust buildup. A clean workspace ensures accurate cuts, reduces the risk of accidents, and prolongs the life of your equipment. Schedule regular deep cleans to keep your setup in optimal condition.

Customization and Storage Solutions

Maximize your workspace with customizable storage solutions. Add wings for extended support and incorporate compartments for tools and accessories. Optimize your garage or workshop for efficiency.

Adding Wings for Extended Support

Extend your miter saw table’s functionality with foldable or fixed wings. These wings provide additional support for longer materials, enhancing stability during cuts. They can be designed to hinge, allowing for space-saving when not in use. Ensure wings are level with the main table for even support. Use sturdy lumber and appropriate hardware to secure them. Consider adding dust collection channels and check the plans for specific brackets or supports. Wings can be customized to fit your workshop needs, improving efficiency and versatility.

Incorporating Storage Compartments

Incorporate storage compartments into your miter saw table for better organization. Add shelves, drawers, or bins to store tools, accessories, and materials. Consider hooks for hanging items like cords or clamps. These compartments maximize workspace efficiency and keep essentials within reach. Foldable wings or extendable shelves can provide additional support while maintaining a compact design. Customize storage solutions based on your needs, ensuring they align with your workshop layout. Detailed plans often include measurements and designs for seamless integration of storage features, enhancing overall functionality.

Optimizing Garage or Workshop Space

Maximize your garage or workshop space with a miter saw table designed for efficiency. Foldable wings and compact designs allow for minimal footprint while maintaining functionality. Consider vertical storage options or wall-mounted accessories to free up floor space. Position the table near other tools to streamline your workflow. Ensure the layout accommodates dust collection and electrical outlets for convenience. These space-saving strategies help create a clutter-free, organized workspace tailored to your needs, whether in a small garage or a larger workshop setting.

Advanced Features and Modifications

Enhance your miter saw table with advanced features like stop blocks for repeat cuts, integrated lighting, and electrical outlets. These modifications streamline workflow and improve precision, ensuring efficient and accurate results in your projects.

Stop Blocks for Repeat Cuts

Stop blocks are essential for achieving consistent and precise repeat cuts. They can be mounted on the side supports of your miter saw table, allowing you to set specific measurements for repetitive tasks. Many free PDF plans include detailed instructions for installing stop blocks, ensuring accuracy and efficiency. By placing the blocks at measured intervals, you can effortlessly make identical cuts without recalibrating each time. This feature is particularly useful for projects requiring multiple identical pieces, saving time and improving workflow. Incorporate stop blocks into your design for enhanced productivity and consistency in your woodworking projects.

Integrated Lighting Systems

Integrated lighting systems enhance visibility and precision while working with your miter saw. Many free PDF plans incorporate LED lighting strips or overhead lights to illuminate the cutting area. These systems are often installed under the table or around the saw, providing even illumination. Improved lighting reduces eye strain and helps maintain accuracy, especially in low-light workshops. Some plans also include adjustable lighting options, allowing you to customize brightness based on your needs. This feature is a practical addition to any miter saw table, ensuring better workflow and safety during projects.

Electrical Outlet Installation

Free miter saw table plans often include options for electrical outlet installation, enhancing convenience and workflow. Built-in outlets provide easy access for power tools, reducing cord clutter. Many PDF guides show how to integrate outlets directly into the table or nearby compartments. This feature is especially useful for workshops with limited plug availability. Some plans also include GFCI-protected outlets for added safety. These installations are optional but offer a practical upgrade for a more functional workspace tailored to your needs.

Troubleshooting Common Issues

Troubleshooting common issues ensures your miter saw table performs optimally. Identify and address problems like blade wobble or alignment inaccuracies to maintain precision and efficiency in your projects.

Addressing Blade Wobble

Blade wobble can significantly affect cutting accuracy. Check the blade for damage or misalignment and ensure the arbor nut is tightened properly. Verify the saw’s alignment with the table and use shims if necessary. Regularly inspect the blade and arbor for wear. If issues persist, consult the manufacturer’s guide or consider professional calibration. Proper adjustment ensures precise cuts and extends blade life. Addressing blade wobble promptly prevents errors in your woodworking projects and maintains the overall performance of your miter saw table.

Fixing Alignment Problems

Alignment issues can arise from an uneven table or mispositioned saw. Start by ensuring the table is level and the saw is securely fastened. Use shims to adjust the saw’s position if necessary. Check the miter saw’s fence alignment with the table edges. If problems persist, refer to the PDF plans for calibration techniques. Proper alignment ensures accurate cuts and prevents uneven results. Regularly inspect and adjust the setup to maintain precision. Downloadable guides often include detailed steps for troubleshooting and fixing alignment issues effectively.

Dealing with Dust Collection Inefficiencies

Dust collection issues often stem from poor connections or blockages. Ensure the dust port is securely attached to the vacuum system. Check for obstructions in hoses or ducts. Regularly clean filters and empty collection bags to maintain airflow. For optimal performance, consider upgrading to a wet/dry vacuum. Some plans include integrated dust collection systems, while others require DIY adaptations. Proper setup and maintenance are crucial for minimizing dust and keeping the workspace clean. Adjustments may be needed to achieve maximum efficiency.

Free miter saw table plans offer cost-effective solutions for enhancing workshop efficiency. With detailed PDF guides, DIY enthusiasts can build sturdy, functional workstations tailored to their needs.

Summarizing the Benefits

Free miter saw table plans offer a cost-effective way to enhance your workshop. Detailed PDF guides provide step-by-step instructions, ensuring sturdy and functional workstations. These plans cater to various needs, from compact designs to large, mobile setups with storage solutions. By following these plans, DIY enthusiasts can achieve professional-grade results, improving workflow efficiency and project accuracy. The availability of customizable options allows users to tailor their workstations to specific tools and spaces, making these plans an invaluable resource for woodworking projects.

Encouraging Further Exploration

Exploring free miter saw table plans PDFs opens up a world of creative possibilities for woodworking projects. With detailed guides and customizable designs, enthusiasts can experiment with unique configurations to suit their workspace. Online communities and forums offer additional inspiration, while downloadable resources provide a starting point for those new to DIY projects. Encourage yourself to dive deeper into the world of woodworking by experimenting with these plans and discovering how they can elevate your craftsmanship and workshop efficiency.

Additional Resources and References

Discover comprehensive guides, cut lists, and 3D diagrams in free miter saw table plans PDFs. Explore recommended websites, books, and forums for detailed woodworking support and inspiration.

Recommended Websites for Plans

Visit websites like The Spruce Crafts and Ana White for free miter saw table plans in PDF format. These sites offer detailed designs, cut lists, and step-by-step instructions. Woodcraft and Fine Woodworking also provide comprehensive guides, ensuring you find the perfect plan for your workshop. Explore these resources to download printable plans and enhance your DIY project experience with expert-approved designs.

Suggested Books and Manuals

For detailed guidance, consider books like “The Miter Saw Handbook” by Gary Hedstrom or “Woodworking with Miter Saws” by Steve Ramsey. These manuals provide comprehensive plans and expert tips for building miter saw tables. Many books include customizable designs and safety advice, ensuring a professional finish. Check platforms like Google Books or Scribd for free PDF versions of these manuals. They are invaluable resources for both beginners and experienced woodworkers, offering step-by-step instructions and project inspiration.

Online Communities and Forums

Join online forums like Reddit’s r/woodworking or Woodworking Talk for miter saw table plan discussions. These communities offer free PDF plans, user reviews, and troubleshooting tips; Engage with DIY enthusiasts, share ideas, and learn from others’ experiences. Platforms like Instructables and Pinterest also host user-generated guides and inspiration. Participate in these forums to enhance your project and discover innovative designs tailored to your needs.

Related Posts

pathfinder 2e remaster pdf

Dive into the epic world of Pathfinder 2nd Edition! Download the complete remaster PDF and unleash thrilling quests, powerful characters, & endless possibilities. Get yours today!

romans study guide pdf

Struggling with Roman history? Get our FREE, easy-to-use study guide in PDF format! Conquer emperors, battles, and culture – download now & boost your grade!

iris kelly doesn’t date pdf

Explore the captivating writings of Iris Kelly! Get instant access to PDFs of her work and discover thought-provoking content. Download now and immerse yourself in her ideas. **Iris Kelly** awaits!